Automation has long been with the forefront of industrial production for decades, even so the rise of robotics has taken it to a complete new degree. Among these breakthroughs, arc welding robots have emerged being a groundbreaking Answer for businesses seeking efficiency, precision, and cost-success.

Table of contents:

the advantages of applying Arc Welding Robots in higher-Precision Manufacturing

How Automation with Welding Robots enhances Workplace Safety

Why Arc Welding Robots are perfect for High-quantity manufacturing traces

These robots, like Those people made by Genius, are redefining important facets of output processes. From boosting place of work safety to enhancing large-quantity production strains, arc welding robots have gotten a staple in industries around the world, reworking production permanently.

the many benefits of applying Arc Welding Robots in large-Precision producing

among the list of clearest benefits of arc welding robots is their Fantastic precision. regardless of whether it’s welding intricate steel factors or sustaining uniformity across batches, automation ensures that just about every solution fulfills the best high quality requirements. For industries including aerospace, automotive, and building, even the smallest inconsistencies in welding may lead to practical inefficiencies or basic safety dangers. Genius, a leading Arc Welding Robot company, integrates Sophisticated systems like high-rigidity robotic arms and laser monitoring, which provide unparalleled accuracy and regularity. With repeatability levels as significant as ± 0.03 mm, these robots can obtain what guide welding only are unable to. Additionally, this improves uniformity throughout generation strains, substantially cutting down waste though guaranteeing consumer pleasure. By buying higher-precision arc welding remedies for instance those provided by Genius Robotics, companies here achieve a competitive edge in Conference the demands of now’s high quality-centric industry.

How Automation with Welding Robots Improves Workplace basic safety

office basic safety has constantly been a priority in industrial manufacturing, particularly when working with welding, a system that inherently consists of large amounts of warmth, harmful fumes, and electrical dangers. Arc welding robots significantly improve security by reducing human exposure to those dangers. Outfitted with capabilities like completely enclosed cables and anti-collision equipment, Genius Arc Welding Robots give an built-in safety Resolution for manufacturing environments. responsibilities for example positioning and welding that after necessary shut human intervention can now be executed by robots, when operators oversee from a secure length. This don't just shields staff but additionally assures compliance with health and security regulations—a significant problem for all makers. An additional noteworthy characteristic Genius incorporates is its noise-tested robotic functions, which maintain degrees beneath 70 dB to make sure a quieter and safer Operating ambiance. By automating hazardous welding functions, producers don't just decrease office accidents and also improve worker allocation, enabling humans to target a lot less risky, benefit-included responsibilities.

Why Arc Welding Robots Are Ideal for substantial-quantity manufacturing strains

For organizations managing superior-volume production, pace and efficiency are essential for maintaining profitability. Arc welding robots, In particular Individuals from trustworthy brands like Genius, prosper in these environments. Their ability to execute repetitive welding responsibilities without exhaustion guarantees sustained productiveness, an element of utmost great importance in speedy-paced generation options. Genius Robotics, amongst China’s leading Arc Welding Robot brands, provides robots Geared up with Fantastic payload ability and advanced movement accuracy. These functions enable their robots to carry out at optimum performance, even if built-in into sophisticated creation methods. Additionally, automation allows decrease direct occasions by getting rid of bottlenecks inside the welding process. Geared up with numerous advanced modes for different welding approaches—for instance CO2, MIG, TIG, and in many cases laser welding—robots from Genius cater to some big range of fabric-precise specifications in industries like automotive and major machinery. Their remarkable technologies not just enhances output pace but in addition ensures that every weld fulfills exacting requirements of top quality. The result? improved throughput, reduced manufacturing expenditures, and more quickly supply to sector—all with no compromising on integrity.

Arc welding robots are becoming indispensable within the realm of industrial manufacturing, providing unmatched precision, enhanced safety, and operational scalability. companies trying to continue to be ahead from the curve and streamline their production procedures can benefit immensely from these automated solutions. For organizations trying to get personalized welding remedies, Genius, a top-tier Arc Welding robotic producer, gives field-major designs and technologies that cater to precise small business requirements. regardless if you are Checking out programs for top-precision producing, workplace safety, or substantial-quantity manufacturing, Genius Robotics gives alternatives that really stand out.

Josh Saviano Then & Now!

Josh Saviano Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Samantha Fox Then & Now!

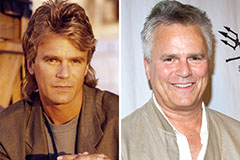

Samantha Fox Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!